|

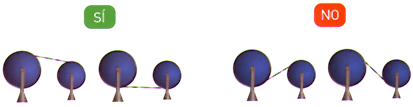

Loads – Single-Leg Slings | Loads – Multi-Leg Slings | |||||

|

|

||||||

| Number of legs, n | – | – | – | 2 legs | 3 & 4 legs | ||

| Inclination angle from vertical, ß | – | – | – | ß>45º | 45º>ß>60º | ß>45º | 45º>ß>60º |

| Angle between opposite legs, a | – | – | – | a>90º | 90º>a>120º | a>90º | 90º>a>120º |

| Factor to calculate Maximum Working Load (MWL), f=n.cosß | 1 | 0.8 | 2 | 1.4 | 1 | 2.1 | 1.5 |

| Webbing width (mm) | MAXIMUM WORKING LOAD MWL (kg) EN 1492-1, safety coefficient 7:1. Balance-loaded, 100% polyester slings | ||||||

| 30 | 1,000 | 800 | 2,000 | 1,400 | 1,000 | 2,100 | 1,500 |

| 60 | 2,000 | 1,600 | 4,000 | 2,800 | 2,000 | 4,200 | 3,000 |

| 90 | 3,000 | 2,400 | 6,000 | 4,200 | 3,000 | 6,300 | 4,500 |

| 120 | 4,000 | 3,200 | 8,000 | 5,600 | 4,000 | 8,400 | 6,000 |

| 150 | 5,000 | 4,000 | 10,000 | 7,000 | 5,000 | 10,500 | 7,500 |

| 180 | 6,000 | 4,800 | 12,000 | 8,400 | 6,000 | 12,600 | 9,000 |

| 240 | 8,000 | 6,400 | 16,000 | 11,200 | 8,000 | 16,800 | 12,000 |

| 300 | 10,000 | 8,000 | 20,000 | 14,000 | 10,000 | 21,000 | 15,000 |

Flat polyester slings EN 1492-1

We were the first manufacturer in the country to offer slings with a 7:1 safety factor, having offered an additional point in the safety factor since 2005.

Our slings are manufactured with 100% high tenacity polyester webbing, which ensures high resistance to abrasion and low elongation.

Advantages of choosing slings ![]()

- Local Manufacturing.

- ISO 9001 Certified manufacturing process.

- Each sling is uniquely identified for better traceability.

- Fast response to special orders.

Recommendations

Unwinding

The coil should be breaked while unwinding so that the wire rope comes out with a certain pressure and does not turn on its axis. This prevents bumps and kinks. If the coil is not equipped with brakes, then an operator should stop it..

Transport between coils

When the wire rope is carried from a full coil to an empty one or to a machine drum, this should be done from the upper or lower part of both, but never from the upper part of one coil and the lower part of the other, or vice versa.

Wire rope winding

The wire rope winding on the machine drum must be carried out correctly so that there are no spires overlapping and cross-linking, which would crush and distort the cords. The following figures represent the four cases that could effectively take place:

- Right torsional wire winding at the upper part of the drum.

The mooring point should be located on the left side of the drum. - Right torsional wire winding at the lower part of the drum.

The mooring point should be located on the right side of the drum. - Left torsional wire winding at the lower part of the drum.

The mooring point should be located on the right side of the drum. - Left torsional wire winding at the lower part of the drum.

The mooring point should be located on the left side of the drum.

We do not recommend winding the wire around the drum in several layers, but if so, this technique is applied for the first layer of winding.

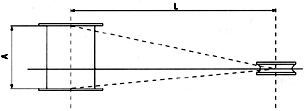

Deflection angle

The deflection angle is that formed by the wire from the first fixed pulley on the edge of the winding drum. It should not exceed 1º 30'.

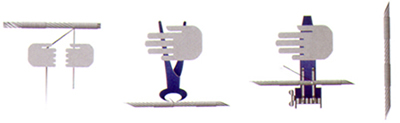

Wire cutting

Cutting with shears or scissors. Before cutting, wires are to be tied together on both sides of the cutting area. The number of ties, the width and the distance between them depend on the wire diameter (see table). It is key to avoid longitudinal tilts among the different cord layers, since, in that case, those which have moved the least will bear the greatest part of the load, and there is the risk of breakage.

| Tie characteristics | ||||

| Wire rope diameter | No. of ties on each side of the cut |

Tie length |

Distance between ties |

Wire diameter rec. iron piece to be used (mm) |

| Up to 12 | 3 | 12 | 15 | 0,5 to 0,8 |

| 13 to 20 | 3 | 25 | 40 | 1 to 1,5 |

| 21 to 30 | 4 | 40 | 50 | 1,2 to 2,2 |

| 31 to 40 | 4 | 50 | 50 | 1,8 to 3 |

| 41 to 50 | 4 | 75 | 50 | 2,2 to 3,2 |

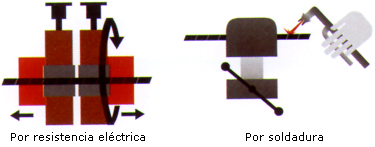

Recommended cuttings

To cut antitwisting wire ropes, we recommend cutting by electric resistance or by welding.

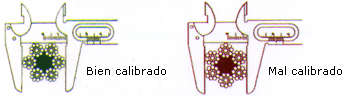

Calibration

For calibration, the measuring device must be properly used.

Information on Polyester Lifting Equipment

ADVANTAGES TO CHOOSING OUR SLINGS

- Local Manufacturing.

- Manufacturing process under IRAM Certification - ISO 9001:2015.

- Each sling is uniquely identified for better traceability.

- Fast response to special orders.

IDENTIFICATION

Keep a record and the corresponding certificate for all slings in use.

The sling must have its identification tag, which must be legible; otherwise, the sling must be discarded.

MAINTENANCE

As with any material, the slings must be appropriately handled and cared for.

Store slings in a clean, dry place, away from direct heat, UV rays, or direct sunlight.

The use of corner protection pieces is always recommended, especially in those places where there is greater risk of cutting or shearing, since the duration of the slings and their safety at work depend, to a great extent, on taking the correct safety precautions.

SAFETY IN USE

- Never overload the equipment. Never use slings not bearing their identification tag.

- Never use damaged slings.

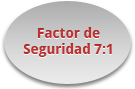

- Place the slings in their correct position. The load must be placed on the slings so that it is evenly distributed across the width of the sling. Slings must never be knotted or twisted. Slings must not be placed near sharp corners. Do not let slings slide above angles, or along corners or edges. Use corner protection pieces along edges.

- Do not drag goods across the slings.

- Position the slings correctly to separate them from the load more easily after their use.

- Use well-rounded hooks.

- Avoid placing more than one sling per hook.

- Whenever you lift heavy loads with more than one sling, remember that it is possible that the total weight is not evenly distributed.

- Remember that vibration during hauling may cause friction. Use corner protection pieces.

- Do not use slings at temperatures above 100°C or lower than -40°C.

INSPECTION

All users of our slings should adopt the following procedure.

Remember: Slings must be examined at intervals of no more than two weeks when used for general lifting, and those used for hauling must be examined before each trip.

Place the slings in a horizontal position, on a flat surface and in a well-lit area.

The full length of the slings must be examined.

Only one person must examine the sling.

The sling must be inspected before each use.

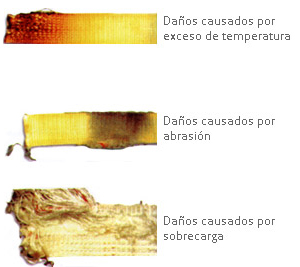

The sling must be discarded if any of the damages included in the picture below are present.