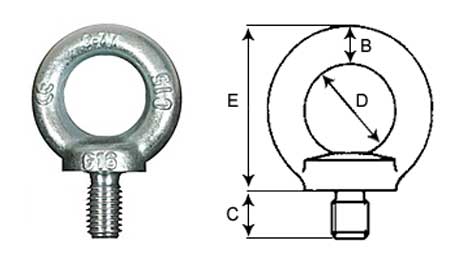

| Metric thread | ||||||

| Dimensions: | SWL in kg 1 eyebolt |

SWL in kg 2 eyebolts at 45° |

Dimensions in mm | |||

| B | C | D | E | |||

| M6 | 70 | 47 | 6 | 13 | 16 | 31 |

| M8 | 140 | 95 | 8 | 13 | 20 | 36 |

| M10 | 230 | 170 | 10 | 17 | 25 | 45 |

| M12 | 340 | 240 | 12 | 20.5 | 30 | 53 |

| M16 | 700 | 500 | 14 | 27 | 35 | 62 |

| M20 | 1,200 | 830 | 16 | 30 | 40 | 71 |

| M24 | 1,800 | 1,270 | 20 | 36 | 50 | 90 |

| M27 | 2,500 | 1,690 | 20 | 38 | 50 | 90 |

| M30 | 3,600 | 2,600 | 24 | 45 | 60 | 109 |

| M36 | 5,100 | 3,700 | 28 | 54 | 70 | 128 |

| M42 | 7,000 | 5,000 | 32 | 63 | 80 | 147 |

| M48 | 8,600 | 6,100 | 38 | 68 | 90 | 168 |

| M56 | 11,500 | 8,300 | 42 | 78 | 100 | 187 |

| M64 | 16,000 | 11,000 | 48 | 90 | 110 | 208 |

| British Standard Whitworth (BSW) Thread | ||||||

| Dimensions: | SWL in kg 1 eyebolt |

SWL in kg 2 eyebolts |

Dimensions in mm | |||

| B | C | D | E | |||

| 1/4″ W | 70 | 47 | 6 | 13 | 16 | 31 |

| 5/16″ W | 140 | 95 | 8 | 13 | 20 | 36 |

| 3/8″ W | 230 | 170 | 10 | 17 | 25 | 45 |

| 1/2″ W | 340 | 240 | 12 | 20.5 | 30 | 53 |

| 5/8″ W | 700 | 500 | 14 | 27 | 35 | 62 |

| 3/4″ W | 1,200 | 830 | 16 | 30 | 40 | 71 |

| 1″ W | 1,800 | 1,270 | 20 | 36 | 50 | 90 |

| 1 1/4″ W | 3,600 | 2,600 | 24 | 45 | 60 | 109 |

| 1 1/2″ W | 5,100 | 3,700 | 28 | 54 | 70 | 128 |