This product line is divided into:

- RED: for low pressure. SLING TPR RED.

- BLUE: for medium pressure. SLING TPR BLUE.

- ORANGE: for high pressure. SLING TPR ORANGE.

| SLING COLOR | CODE | ø PIPE/PRESSURE | RECOMMENDED SHACKLE |

| RED | 5-PES-TPR-ROJO-4M | 2” Maximum Pressure 15K psi | 7-GRI-0650-G2130 6.5 Ton |

| 3” Maximum Pressure 8K psi | |||

| 4” Maximum Pressure 5K psi | |||

| BLUE | 5-PES-TPR-AZUL-4M | 2” Maximum Pressure 20K psi | 7-GRI-0850-G2130 8.5 Ton |

| 3” Maximum Pressure 15K psi | |||

| 4” Maximum Pressure 10K psi | |||

| ORANGE | 5-PES-TPR-NARANJA-4M | 2” Maximum Pressure 20K psi | 7-GRI-1200-G2130 12 Ton |

| 3” Maximum Pressure 15K psi | |||

| 4” Maximum Pressure 15K psi |

Use

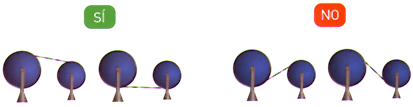

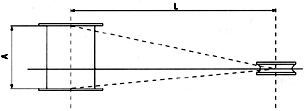

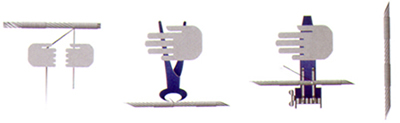

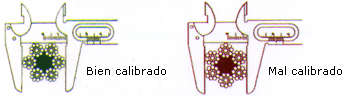

- Slings are connected as a bow to the pipeline at strategic points, and they are assembled with other slings through shackles.

- The use of shackles simplifies system assembly and disassembly; speeds up localized disassembly, eventual reparations or stamps changes; thus, reducing operational times. Every IZT retention sling has its own identification tag with the relationships between pipe diameters and maximum pressures allowed. Tested in dynamic scenarios that recreate a pressure pipelines failure situation.